“Bargain” Organs with Soft 3-D Printing

Artificial heart targeted…

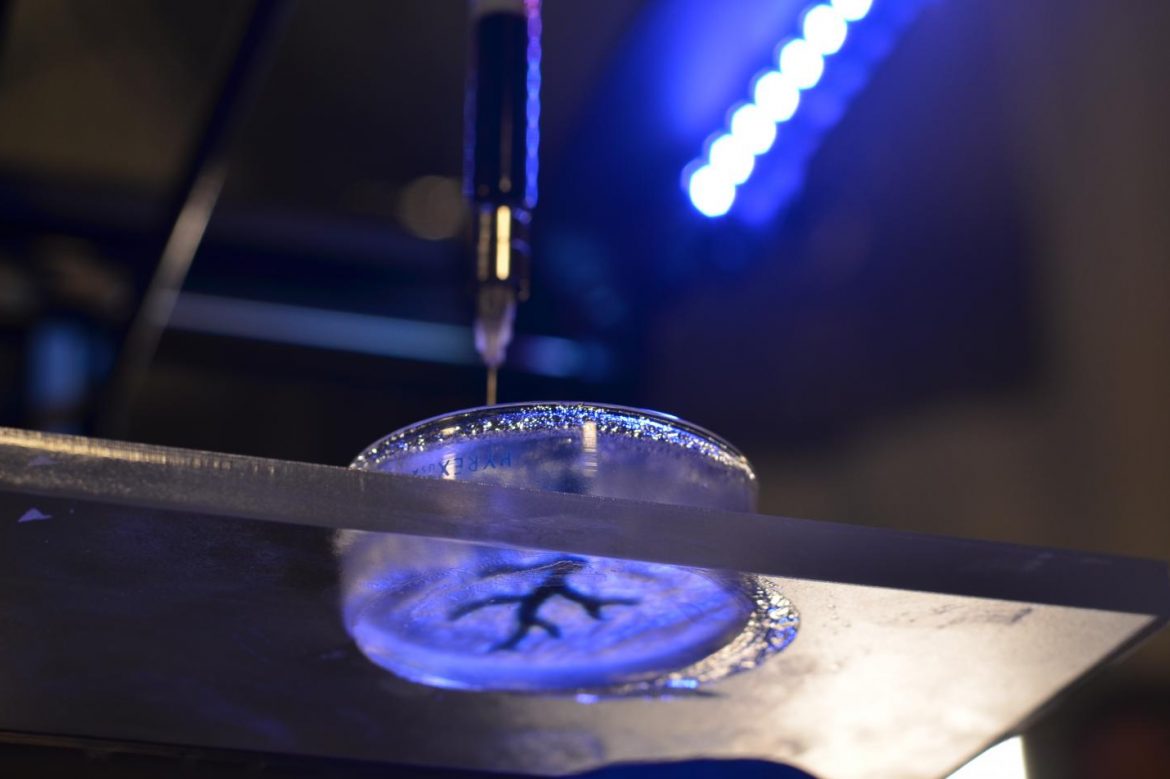

Taking an important step towards the production artificial organs in laboratories to eliminate the dependence on risky and expensive transplants, researchers at the Carnegie Mellon University created copies of a miniature brain, the heart of a baby chicken and a branching cardiac artery with a novel and imaginative 3-D printing technique using soft materials.

The 3-D printing technology which has found an ever-widening range of applications over the last decade, is based on the printing of the copies of various objects in layers, typically made of plastic or metals, piled one after the other with the aid of computer programs.

But implementing this technique with soft materials had proved impossible so far owing to the tendency of the bottom layers suspended in air or in water to disintegrate or get crushed under the weight of the layers above. The solution brought to the problem by the Carnegie Mellon team led by biomedical engineer Adam Feinberg was to use elastic jell-o-like materials such as fibrin, collagen or alginates derived from seaweed for the printed layers and build the structures embedded in a different gel. The biological structure to be copied is first imaged in thin sections with magnetic resonance imaging (MRI) equipment or precision microscopes. Then, the objects constructed with the FRESH (Freeform Reversible Embedding of Suspended Hydrogels) technology emerge after the support gel melts away under body temperature.

An advantage of the method is the utilization of readymade, open source computer programs instead of tailor-made ones as well as the use of cheap raw materials that can be easily obtained from the market.

Thus while the hard 3-D equipment normally cost about 100,000 dollars, the cost bracket for the products developed by the Carnegie Mellon is 500-1000 dollars.

The new target of the team is making porous structures in which natural or artificial cells could be embedded to enable the production of functional tissues that can be used to repair damaged hearts or other organs.

REFERENCES

- 1. “Carnegie Mellon Resarchers hack off-the-shelf 3-D printer towards rebuilding heart”. Carnegie Mellon University, 23 Octobre 2015

- 2. “3D printing soft body parts: A hard problem that just got easier”, ScienceOnline, 23 Octobre 2015