Hydrogen Energy: Present and Future

We are all aware that the world is grappling with the challenges of global warming. Among various solutions, hydrogen energy stands out prominently. Professor Can Erkey from Koç University, Department of Chemical and Biological Engineering, is among those asserting that hydrogen will play a crucial role in addressing the global warming issue and achieving the goal of carbon neutrality by 2050.

Hydrogen, an element that has recently gained significant attention, is the most abundant substance in the universe. It is odourless, colourless, tasteless, and flammable, yet it permeates every aspect of our lives. It constitutes three-quarters of the Sun, the celestial body vital for life on Earth. Hydrogen is found in all plant and animal tissues and exists in countless carbon compounds. Despite comprising a mere 0.14% of the Earth’s crust by mass, it is abundantly present in oceans, glaciers, rivers, and the atmosphere.

Under standard conditions, hydrogen exists as a gas, forming loose diatomic hydrogen molecules (H2). On our planet, it often combines with other elements. Notably, its key property, discovered in the early stages of chemistry, lies in its reaction with oxygen to create water (H2O). The very term “hydrogen” originates from the Greek, meaning “water-forming” (a point of homage to the renowned French scientist Lavoisier).

Hydrogen is extensively used in various industries, contributing to the production of raw materials such as plastics, explosives, textiles, and pesticides. Its primary industrial function is in the production of ammonia (NH3), with approximately 80% of global ammonia production utilized in synthetic agricultural products, particularly fertilisers.

Beyond its industrial applications, hydrogen has quietly entered our daily lives due to its potential as a fuel owing to its flammability. Unlike fossil fuels, the sole by-product of combustion of hydrogen is water vapour, with no emission of greenhouse gases.

By weight (mass), it contains about three times more energy than fossil fuels, necessitating only one-third of the amount of fossil fuels for equivalent work. However, its low volumetric energy density requires advancements in storage and transportation technologies. Given that hydrogen is usually not freely available in nature, extraction from other sources (fossil fuels, water, or biomass) is necessary, leading to its designation as an energy carrier. The crucial aspect lies in the separation of hydrogen atoms from other elements to obtain pure hydrogen, and the method employed in this process profoundly influences the sustainability of hydrogen as a fuel.

However, despite its immense energy potential, the current predominant method of hydrogen production relies heavily on fossil fuels. Approximately 96% of industrial hydrogen production is carried out by a process known as steam methane reforming. In this method, at elevated temperatures, water vapour reacts with methane (natural gas) in the presence of a catalyst, yielding hydrogen and carbon dioxide (CO2), a greenhouse gas. Subsequently, in a purification step, carbon dioxide is extracted, resulting in the production of pure hydrogen.

The hydrogen generated through this process is termed “grey hydrogen” as it originates from fossil fuels, consequently contributing to significant greenhouse gas emissions. In an effort to mitigate environmental impact, if the CO2 produced during this process is captured and stored elsewhere, the resulting hydrogen is termed “blue hydrogen.”

An alternative method for hydrogen production involves electrolysis. By subjecting water to an electric current, the hydrogen and oxygen atoms constituting water molecules are separated, with only oxygen remaining as a by-product or waste, while the hydrogen is stored separately. When this electrolysis process is executed using renewable energy sources, it is labelled as “green hydrogen.” However, the current challenge lies in the relative cost of the reactors, known as electrolysers, and the inefficiency of the process. The cost of renewable energy is also a major contributor to the cost of green hydrogen. Moreover, improvements are needed in the pressurized systems utilized for storing the resultant hydrogen. Nevertheless, there is a promising prospect of overcoming these partial obstacles in the near future, paving the way for the widespread adoption of green hydrogen.

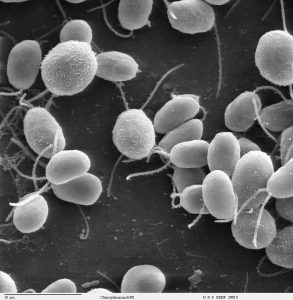

Biological processes also offer a potential avenue for hydrogen production, though industrial-scale applications remain in the developmental stage. Certain algae species play a role in separating oxygen and hydrogen atoms during the photosynthesis process and subsequently convert hydrogen into a gaseous form using an enzyme called hydrogenase. The well-known Chlamydomonas reinhardtii is one such algae, while others like Scenedesmus obliquus, Chlorococcum littorale, and Platymonas subcordiformis can also be used for the same purpose. The primary challenge in scaling up these applications lies in the efficiency of reactors converting solar energy into chemical energy, necessitating the development of more economically viable bioreactor designs. Additionally, efforts are underway to enhance the efficiency of hydrogen production by these algae through genetic interventions.

Regardless of the method used to produce hydrogen for fuel, a significant limitation to its practical application lies in storage methods. Hydrogen can be physically stored either in a gaseous or liquid state. Storing hydrogen in its gaseous form necessitates high-pressure tanks (300 – 1000 atm). On the other hand, storing hydrogen in liquid form requires extremely low temperatures, given that the boiling point of liquid hydrogen under one atmosphere of pressure is -252.8°C. With current technological capabilities, storing hydrogen in gaseous form is feasible in large tanks at stationary power plants. However, the challenge persists when it comes to portable energy sources, particularly in the context of transportation vehicles powered by fuel cells.

Fuel cells can be likened to batteries with a distinctive feature —they don’t deplete or require recharging. They keep generating electricity and heat as long as a continuous supply of fuel is provided and are essentially composed of two electrodes placed on either side of a conductive polymer, one positively charged (cathode) and the other negatively charged (anode). Hydrogen is delivered to the anode, while air is supplied to the cathode.

Polymer Electrolyte Membrane fuel cells, commonly known as PEMs, represent a significant type of fuel cell, often fuelled by hydrogen. These cells employ a catalyst that separates protons from electrons, allowing the electrons to traverse an external circuit, generating an electric current. Simultaneously, protons travel through the electrolyte to the cathode, where they reunite with oxygen and electrons to produce heat and water. Notably, the catalyst used in hydrogen fuel cells is platinum, contributing to its relatively high cost. Ongoing research aims to explore methods for cost reduction in platinum usage.

Currently, PEM fuel cells stand out as a leading candidate for powering cars and especially heavy-duty vehicles. Operating at relatively low temperatures, they can swiftly fulfil the demand for electric current at various power levels. Their efficiency, reported to be up to 60% higher than internal combustion engines, stems from their ability to directly convert the chemical energy in the fuel into electrical energy. Beyond their efficiency, PEM fuel cells offer additional advantages —they operate silently and produce no greenhouse gas emissions, contributing positively to global warming mitigation and public health.

Technological advancements in hydrogen energy have progressed well beyond their initial stages. Major companies like General Electric and Rolls Royce are actively involved in designing and deploying hydrogen-powered power plants and compact units. Notably, Rolls Royce, in collaboration with British airline EasyJet, successfully tested an aircraft engine powered by green hydrogen last year, showcasing the viability of achieving net-zero carbon flights in the near future.

The European Union has also prioritised hydrogen in its agenda, envisioning a transition to a carbon-neutral energy system by 2050 and aiming to lead in this endeavour. A decision made in 2020 by the Commission involves setting targets and initiating efforts to replace existing grey hydrogen systems with green hydrogen. An ambitious goal includes establishing a hydrogen filling station every 200 km by 2030. Moreover, there is a strong emphasis on promoting the use of green hydrogen in high carbon-emitting industries such as iron and steel, cement, petrochemicals, and glass.

Fuel cell electric vehicles (FCEVs) are already making their way into the market, with California, a leading state in the United States, boasting a total of 52 hydrogen filling stations as of 2023, and an additional 45 stations under construction. Notably, US President Joe Biden recently announced a $7 billion stimulus package aimed at bolstering hydrogen production and consumption within the country.

Despite these advancements, a significant hurdle remains, primarily in the realm of storage. The conventional approach, requiring a single tank of fuel to cover approximately 500 km, necessitates storing 5-13 kg of compressed hydrogen gas in a vehicle, contributing to elevated costs. Moreover, the current cost of hydrogen, which is two to three times higher than gasoline, poses a common obstacle to wider adoption.

Indeed, there are scientists who envision a transition to a hydrogen-based economic system in the foreseeable future. Prof. Can Erkey, an expert on the subject in Türkiye and a member of the Department of Chemical and Biological Engineering at Koç University, predicts a transformative shift where hydrogen stations could replace traditional gasoline stations. Prof. Erkey suggests that such a transition is feasible within the next 20 years. However, he also emphasizes the formidable challenge ahead, acknowledging that the existing industrial infrastructure, valued in trillions of dollars and rooted in fossil fuels, will need to undergo a substantial and complex transformation –which will not be easy.

KURIOUS: Could you briefly describe us the working principles of PEM fuel cells?

Can Erkey: A Polymer Electrolyte Membrane (PEM) fuel cell can be thought of as a battery, but it doesn’t run out and doesn’t need to be recharged; it continues to generate electricity as long as you supply the fuel, which is hydrogen in our case. It consists of a cathode and an anode, placed on both sides of a proton-conducting polymer. When hydrogen is supplied to the anode, it is split into protons and electrons by the catalyst. The protons pass through the conductive polymer to the cathode, while the electrons pass through the external circuit and create an electric current. These electrons then react with protons and oxygen in the cathode with the catalyst to form water vapour.

KURIOUS: To make hydrogen a more common energy source, what advancements are necessary in PEM fuel cells and hydrogen production technologies?

Can Erkey: For green hydrogen to effectively compete with fossil fuels, its cost must decrease to approximately 1.5-2 dollars per kilogram. Achieving this requires further reductions in the costs of renewable energies and electrolysers. Lowering electrolyser prices can be accomplished by enhancing their efficiency and lifespan, as well as exploring alternatives to the expensive materials currently employed in their production furthermore, the prices of renewable energy can be brought down through the widespread commercialization of more efficient solar cells. Improving the efficiency and longevity of PEM fuel cells is also crucial on the demand side, necessitating a reduction in the usage of precious metals like platinum in the electrodes.

KURIOUS: Can you give our readers an overview of the projects you are currently working on?

Can Erkey: I have recently been dedicated to advancing PEM electrolysers, concentrating on their role in green hydrogen production. My focus spans the entire spectrum of development, including the design, production, and optimisation of the film-shaped catalyst structures embedded within these devices. Additionally, my research extends to the design, optimisation, and production of porous transfer layers, aimed at enhancing the efficient elimination of gases from the electrodes. I am also actively engaged in the efficient integration of PEM electrolysers with renewable energy sources, seeking innovative ways to seamlessly combine these technologies for optimal performance and sustainability.

KURIOUS: What do you think about the future of hydrogen energy and its potential in our country?

Can Erkey: Hydrogen is poised to play a pivotal role in addressing the global warming crisis and attaining the ambitious target of carbon neutrality by 2050. Given our nation’s abundance of renewable energy resources, we have significant potential to produce green hydrogen for export to Europe. Consequently, it becomes imperative to spearhead the development of green hydrogen production technologies, improve hydrogen transportation and storage infrastructure, promote widespread adoption of hydrogen in both industrial and transportation sectors, foster the requisite human resources in this domain, and institute supporting legislative frameworks. It is also crucial to foster increased collaboration among the public sector, private enterprises, and academic institutions in the realm of hydrogen.

REFERENCES

- 1. https://www.health.ny.gov/environmental/emergency/chemical_terrorism/ammonia_tech.htm

- 2. https://www.nrel.gov/research/eds-hydrogen.html

- 3. https://www.sciencedirect.com/science/article/pii/S258929912030001X

- 4. https://www.energy.gov/eere/fuelcells/hydrogen-storage

- 5. https://www.energy.gov/eere/fuelcells/fuel-cell-basics

- 6. https://www.energy.gov/eere/fuelcells/fuel-cells

- 7. https://www.sciencedirect.com/science/article/pii/S258929912030001X

- 8. https://www.airport-technology.com/news/rolls-royce-tests-hydrogen-take-off-conditions

- 9. https://www.europarl.europa.eu/news/en/headlines/society/20210512STO04004/renewable-hydrogen-what-are-the-benefits-for-the-eu

- 10. https://news.climate.columbia.edu/2021/01/07/need-green-hydrogen/

- 11. https://afdc.energy.gov/fuels/hydrogen_basics.html