Constructing Earthquake-Resilient Structures

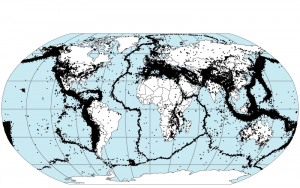

Living in an earthquake zone requires the ability to build structures resilient to earthquakes. The way to do this relies on using scientific and technical knowledge. Many details need to be considered and inspected, not only during the construction of buildings but during all stages, starting with the production of materials to be used in construction. Of course, the work starts with the ground investigation, especially if you are in an earthquake-prone area.

Civil Engineer Murat Sarıerler, whom we interviewed on the subject, has been involved in many different projects, from residential buildings to hotels and shopping malls, dams to roads, and viaducts. In these projects, he has successfully worked in many branches including structural engineering, planning management, and project control management in international construction works. He gave us valuable information on several issues, from ground investigation to design details, from the production of construction materials to things to consider during their applications.

First, let’s consider the ground. Ground investigation is literally “vital” when you want to build any structure in a particular location. A valid ground investigation looks at many variables regarding underground layers, including the geological structure, thickness and density, rock-soil composition, and even electrical resistivity. It also makes an extensive examination of features such as the depth of underground water and its effect on ground layers, the earthquake risk degree of the region, and the distance to any fault. All these reveal whether the ground is suitable for construction. In order to build a structure that can be supported by the environment and that will show the expected strength during an earthquake, a proper ground investigation is a must. The entire project design of the construction must be based on this investigation report, step by step. “This is where the first problem arises,” says Sarıerler, “it is extremely inconvenient to use the average values for a region or to look at ground investigation reports of adjacent buildings to save time and cut back on the cost.”

So, what must be done to create a proper foundation project for a building?

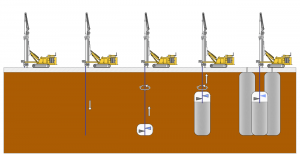

Normally, drill samples to be examined are taken from a number of specific points, covering the entire project site. These examinations and reports are made by geological or geophysical engineers. They decide on which points to drill and report whether there is any ground that needs to be removed or improved. In case the entire ground or a part of it is found to be in poor condition, you have the option to either relocate the project or improve the ground, keeping the costs at an optimum. In order to give the decision on ground improvement, you will need the ground investigation report, drilling logs, and a geotechnical report. In light of these data, a ground improvement project is created. The civil engineer’s responsibility is to create a foundation project that fits the ground’s current condition or its final condition if any improvement is to be made. The decision on whether to use any piling, jet grouting, or another system is made based on the ground’s structure and condition. The most important issue is to design a project, where the ground and reinforced concrete systems complete each other.

What can be done for grounds where high groundwater or a runny texture is in question?

First, we determine the upper and lower water levels and excavate the ground until the lower level. The water is then drained out of the working area. According to the characteristics of the structure, or the project, we determine how much deeper we should go down from the lower level and we continue descending until that level, which we call the sub-basement level. We first pour lean concrete, a rough type of concrete onto the wet basin. The purpose here is to cut the interaction between the ground and the foundation in order to protect the foundation concrete. On top of that, we apply insulation, then the foundation concrete, and then place the reinforcing bars (we call them rebars). All these allow for building a safe structure on the correct ground, which is improved and in line with the project.

What if the ground is on a fault?

Frankly, we do not recommend building anything on grounds formed on faults, stream beds, or alluvium. In retrospect, people generally settled on mountain slopes or similar solid grounds. The plains were left for agricultural purposes. In terms of engineering solutions, it is virtually possible to build any kind of structure on any ground, but you need to consider the profit-loss balance well when making such decisions. However, if you will proceed with the construction, there are various technologies you may use such as shear keys, neoprene, or seismic isolators. Seismic isolators reduce the intensity of seismic waves and prevent tilting. Rail systems, for example, are used in Japan. There are also special carbon fibre or similar materials you may wrap around the columns, over the concrete. These are especially recommended for use in viaducts and while retrofitting buildings. These prevent the concrete from bursting or crumbling when it does burst.

Are there any extra measures you can take, apart from the ground?

The earthquake load acting on a building is proportional to its weight of it. Therefore, the best thing to do is to reduce the building load. You can use lighter materials in construction. For example, steel and wood are both durable and flexible materials. There are also R&D studies on structural steel for use in special high-budget projects.

Let’s talk about support systems. Today, the two basic materials that form the backbone of most buildings are iron and concrete. What are the important details about these two materials?

A good unison of concrete and rebars is essential for the durability of a structure. In case of a tremor, the concrete tends to keep the structure, while the rebar pulls. The rebar’s tensile strength and flexibility depend on its carbon content. If the rebar’s carbon content is higher than necessary, its flexibility decreases below the limits given in the regulations, and the rebar becomes brittle. Therefore, it is critical to pay attention to this ratio during its production. Then, the iron is taken for a tensile test to determine its yield strength, that is, how much it stretches and bends, and when it breaks.

Concrete, on the other hand, is like a baby. You need to pay attention to so many details from its production to application. You have to attend to and supervise every step. For example, for each concrete class, you need to use an aggregate (gravel) produced in sizes suitable for that particular class. If you use pieces larger than these dimensions, you cannot have a homogeneous concrete mixture. Reinforced concrete elements manufactured with this heterogeneous concrete will have cavities inside, they will not reach the required strength and be unable to perform their duty. In case ingredients such as sea or river sand will be used, they must be washed. Otherwise, unwanted substances will contaminate the concrete mix and lead to certain chemical reactions that may make the concrete brittle. Alkali-silica materials also increase chemical reactions in structures exposed to wetting and drying, shortening the life of the concrete. For similar reasons, your binding material, cement should have a chemical structure that fits other ingredients in the mixture.

The water-cement ratio in the mix is also critical. Each concrete type has a specific recipe, and unless you follow that recipe, you will end up with low-quality concrete. Ready-mixed concrete is produced in accordance with these, having fixed values and consistency. Adding water to ready-mixed concrete will alter the water-cement ratio and change the concrete class. You must pour the concrete within three hours of leaving the facility. If you exceed this time, the concrete will burn and should not be used according to regulations. When the concrete burns, the cement decomposes and the mixture becomes sand-like. After it is poured, the concrete must be cured for a week. This is a kind of controlled cooling. If skipped, the concrete may burn. When you are going to pour a thick layer of concrete, you must use special methods to prevent the outermost part from cooling too quickly, causing cracks inside the middle parts. In such cases, cooling pipes and serpentine systems are applied inside the foundations to control the heat of hydration. Even the ambient temperature while pouring the concrete is important because the concrete’s temperature should not fall below +4 degrees. In very cold weather, antifreeze should be applied to the concrete at the time of pouring, then it should be protected by wrapping it with a blanket or by controlled heating with external systems. So, the ingredient and proportions, transport conditions and duration, pouring method, slump value, its consistency and temperature, and even air temperature are all important and must be supervised. Lack of control in any of these steps reduces the life of the concrete and its compressive strength.

Any other details regarding the columns and beams that make up the support system?

You must ensure a proper binding of the concrete and rebars. For example, when connecting rebars, you must leave specific gaps between them in line with the project, so that the concrete can pass through. These gaps should be adjusted according to the diameter of the rebars and the maximum aggregate size in the concrete mixture you use. Otherwise, the concrete cannot completely cover rebars, creating weakened points. To ensure that the concrete also doesn’t have gaps or air pockets, the vibration must be applied during placement. The ribs on rebars provide a stronger binding between the concrete and the bar. Also, additional elements such as water pipes and electrical cables should not run through load-bearing elements. These disrupt the integrity of columns and reduce their strength. Supervising is essential and vital at every step of construction. And at every step, the staff should also have professional competence and necessary certificates. The way to ensure this is to highlight concepts such as awareness and multi-disciplinary approach even in the early stages of education. As in the past, theoretical knowledge must be complemented with knowledge on applications that should be learned in the field with a master-apprentice relationship. Engineers should also receive training in post-disaster search and rescue, damage assessment and coordination. In fact, these engineers should be included in search and rescue efforts.

After the Earthquake, or Before the Next One

Days after the earthquake, while search and rescue efforts continue in the region, scientists are also taking part in several boards to join forces around the concern of “What can we do?” and “What should we do?” for those who got affected by the earthquake.

Prof. Sibel Salman from Koç University’s Department of Industrial Engineering has been working on disaster management for nearly 20 years. Together with other scientists working on this subject, they first applied to TÜBİTAK to offer their support. Their application was immediately transferred to AFAD, and the very next day, they were on the way to Gaziantep with a group of experts consisting mainly of geoscientists and civil engineers, under the umbrella of the AFAD General Directorate of Earthquake and Risk Reduction. According to the information received from the Ministry of Environment and Urbanization, they learned that the plan was to build 400 thousand houses in 11 provinces in areas close to TOKİ houses, for which ground investigations have already been carried out. Additionally, the academicians formed subgroups to receive support for new constructions to be made in line with the new master plans for both other residential areas and the old city centres.

Prof. Sibel Salman is also the coordinator of the logistics group, which will work on temporary accommodation, and they will plan service and material acquisition for container cities. They will monitor the mobility of this large population across the country and prepare settlement plans for these newly established cities. For all these, they will use algorithms that will be created with the help of mathematical models that will first make an accurate identification of the needs and goals. The primary goal here is “equity and fairness”! Through methods such as statistical data analysis and machine learning, they will create algorithms that include all constraints and will provide the best solutions. Of course, these studies will not be limited to today, and will be preserved as critical resources for future use in case of possible earthquakes.

What about earthquake risk analyses and retrofits in existing buildings?

First, an evaluation report is prepared in regard to the current condition and available data. However, if the building was constructed according to the regulation before 2021, we cannot expect it to comply with the earthquake analysis values in the new regulation. The new one includes increased minimum dimensions of column-beam sections, as well as improved earthquake load and calculation methods. In light of these reports, the engineers first evaluate the ground’s condition, whether the static and foundation systems in the building are compatible with the ground conditions, and whether the building is made in accordance with its project in general. Depending on the age of the structure, they also determine the concrete strength and reinforced concrete fatigue based on regulations. A Schmidt hammer is used for a concrete hardness test, core samples are taken and broken apart to check the load-bearing capacity of the concrete. The support system is then examined with special imaging techniques to determine whether it has been constructed in accordance with the static project, whether the correct size of rebars was used, and whether enough concrete cover was left. The building is also checked for heavy damage or any other problems. If the building was constructed in accordance with its project; it is time to decide which improvements and retrofits should be applied to meet the standards given by the new regulation. In case the foundation dimensions require any changes, the perimeter of the foundation is excavated and epoxy-based materials are injected. We may also attach rebars to increase the concrete sections. Concrete sections can also be increased by anchoring rebars to column-beam systems. Carbon fibre materials used against earthquakes may be wrapped on columns to further enhance measures to reduce deformation. In case the building lacks shear walls to take the earthquake load, we may place special steel cross-bars inside the column-beam systems, or transform the column systems into shears from the foundation all the way up to the roof. In the end, a new static calculation is created and the existing reinforced concrete system becomes evolved. The building now operates according to this new static system. Of course, at this point, the responsibility now rests on the person that makes all those calculations. In terms of strength, the building reaches a level that can withstand an earthquake, but a certain part of it will have reached a certain age. Therefore, for very old buildings, these applications should be evaluated carefully. Sometimes constructing from scratch can be much cheaper, safer, and more meaningful.